CUSHION COURSE

YOUR MAKES

YOUR REVIEWS

CALCULATORS

ABOUT US

CONTACT US

MATERIALS

TOOLS

PRICES

PRO SUBSCRIPTION

LOG IN

CUSHION COURSE

YOUR MAKES

YOUR REVIEWS

CALCULATORS

ABOUT US

CONTACT US

MATERIALS

TOOLS

PRICES

PRO SUBSCRIPTION

LOG IN

You now have the finished blind width, length and a preferred Top Section Size. Next you need to calculate the number of rod pockets on the back of the blind and their positions. This will determine the style and depth of the blind when it is pulled up.

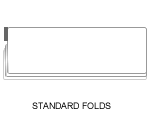

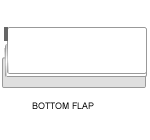

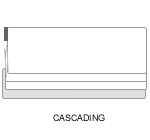

The making process is the same for all 3 styles of blind, the only difference is the calculation of the number of rod pockets and their positions. In this core tutorial we will be making a standard folds blind where flaps all line up in the up position. If you are making a cascading blind or a blind with an extended bottom flap, see the links at the bottom of the page for some extra information.

DETERMINE YOUR HEADRAIL ALLOWANCE

First we need to establish the Headrail Allowance

The headrail allowance must be sufficient to cover the batten/headrail face and allow enough room under the blind for the folds to pull up to the correct position.

It is fine to have a headrail allowance longer than the minimum, but the blind will not pull up properly if the headrail allowance is too short. In the workroom we use a minimum of 6.5cm for headrail allowance for our headrails. As a general rule use an absolute minimum headrail allowance of:

Headrail mechanisim: Headrail depth + 2.5cmTraditional wooden batten: Batten face + 3.5cm

Please see our BASICS article HEADRAIL ALLOWANCE EXPLAINED for more detailSTANDARD FOLDS CALCULATION

PRO TIPS

Yes that is normal,standard folds form a very slight cascade due to the way the rods and rings stack on each other when the blind is pulled up. The calculation of the rod pocket positions means that if the rods were all pulled up to exactly the same height, all the folds would be exactly inline. (see image)

However that is not how a blind pulls up, the rods and rings stack on each other on the cord which creates a very slight cascade. If you were really wanting to make the folds line up exactly inline you would have to make make an adjustment to your rod pocket position calculation . It would involve making a mock up to see what the slight cascade depth is caused by the type of rod pockets and ring/breakouts you are using. Then recalculating the rod pocket positions to adjust for this. (this is not something we do)